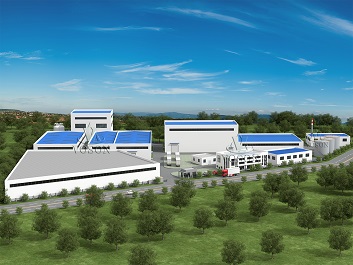

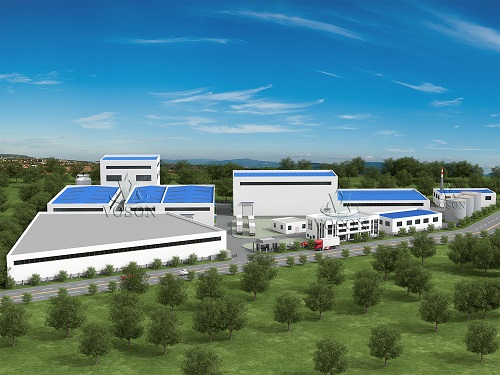

500 T/D Cottonseed Oil Production Line Project

Henan Voson Grain Engineering Machinery provided an efficient and stable 500 t/d cottonseed oil production line solution, helping increase production efficiency, improve oil quality, and achieve sustainable development. This project covers the entire process, from raw material pretreatment to refined oil, ensuring high oil recovery rates and superior product quality.Get Details

500 T/D Cottonseed Oil Production Line Solution

To ensure the smooth implementation of the project, we provided a complete set of equipment and technology that meets international standards, covering key processes such as raw material pretreatment, oil extraction, oil refining, filtration, and packaging.

1、Raw Material Pretreatment

Cottonseeds are strictly screened, cleaned, cracked, and steamed to ensure purity and prepare them for extraction. The equipment used includes:

Screening Machine: Removes impurities from the cottonseeds.

Cleaning Machine: Thoroughly cleans the surface of the cottonseeds to ensure no contamination.

Crushing Machine: Increases the surface area of the cottonseeds to facilitate better extraction.

Steaming Machine: Uses heat and steam to make oil release more easily from the seeds.Get Details

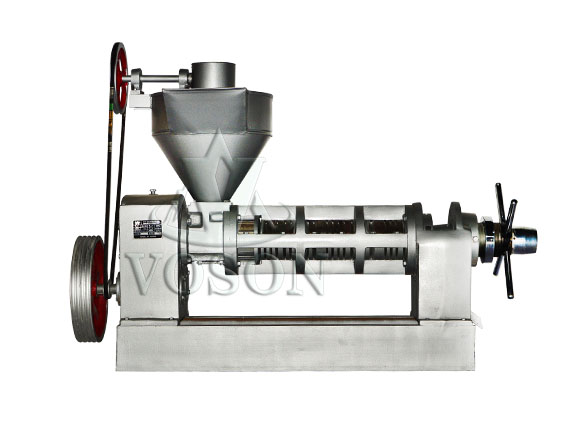

2、Oil Extraction

For the oil extraction process, we combined screw press extraction and solvent extraction technology to maximize oil recovery and improve production efficiency. The oil cake after pressing is further extracted using solvent extraction to achieve high oil recovery rates.

3. Refining Process

To ensure the quality of the cottonseed oil, we provided advanced refining technologies, including deacidification, decolorization, and deodorization processes:

Deacidifier: Removes free fatty acids and lowers the acidity of the oil.

Decolorization Tower: Removes pigments to make the oil clearer and more transparent.

Deodorization Tower: Removes odors to ensure the oil is flavor-neutral and pure.

4、Filtration and Packaging

After refining, the oil is filtered to remove any remaining fine impurities, ensuring the final product is pure. Then, the oil is packaged using an automated filling and packaging system, ensuring freshness and quality in each bottle.Get Details

Why Choose Voson?

Customized Solutions: We provide tailor-made solutions based on client needs, ensuring optimal equipment and production processes.

Advanced Technology & Equipment: Voson uses world-leading technologies to provide efficient and stable equipment, maximizing oil recovery.

Comprehensive Support: From equipment installation and commissioning to production line training, we offer full after-sales service to ensure the smooth implementation and continued operation of the project.Get Details