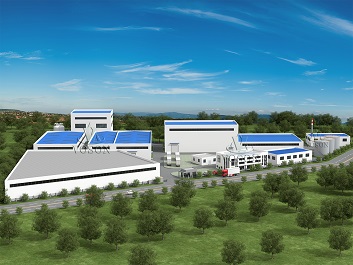

Complete soybean oil production line

A complete soybean oil production line involves a series of steps starting from seed preparation to oil extraction, refining, and final packaging. Each stage is critical for ensuring high-quality soybean oil suitable for various food, industrial, and pharmaceutical applications. Efficient processing techniques and quality control measures are essential to maximize oil yield and maintain product integrity throughout the production process.

1. Soybean Seed Cleaning and Preparation

- Seed Cleaning:

- The soybeans are thoroughly cleaned to remove dirt, stones, and other impurities.

- Seed Dehulling:

- In some cases, the outer hull of the soybeans may be removed to improve oil extraction efficiency.

2. Soybean Oil Extraction

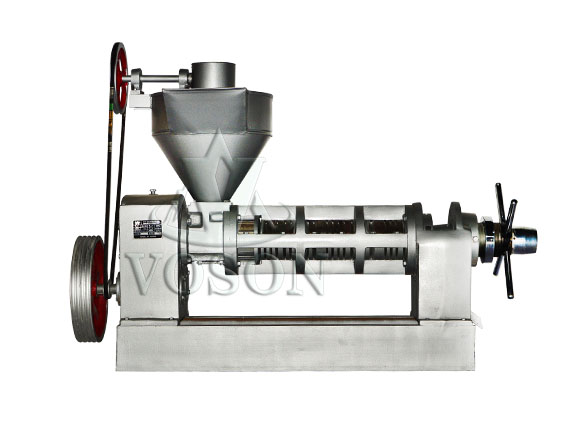

- Mechanical Pressing:

- Cleaned and prepared soybeans are fed into a mechanical press to extract crude oil. This process involves pressing the soybeans under high pressure to release the oil.

- Solvent Extraction:

- After mechanical pressing, the remaining soybean meal (oil cake) undergoes solvent extraction using hexane or other organic solvents to extract additional oil. This step is crucial for maximizing oil yield from the soybean meal.

3. Oil Refining

- Degumming:

- Crude soybean oil is treated with water or acid to remove phospholipids and other impurities.

- Neutralization:

- The oil undergoes neutralization with an alkali (e.g., sodium hydroxide) to remove free fatty acids.

- Bleaching:

- The oil is bleached with activated clay or other adsorbents to remove pigments and improve clarity.

- Deodorization:

- The refined oil undergoes steam distillation at high temperature and vacuum to remove odors and improve flavor stability.

4. Oil Fractionation (Optional)

- Fractionation:

- The refined oil can undergo fractionation to separate different triglycerides and obtain specific fractions such as olein and stearin for different applications.

Complete soybean oil production line involves multiple processes and equipment, and each step has its specific purpose and technical requirements to ensure the quality and safety of the final product.Get a Free Design