The cottonseed oil extraction process (cottonseed oil project) typically includes the following main steps:

Seed Cleaning: Cottonseeds are cleaned to remove dirt, debris, and other impurities.

Seed Dehulling: The outer husks or hulls of the cottonseeds are removed.

Seed Flaking: The dehulled cottonseeds are flattened into flakes to increase the surface area for oil extraction.

Cooking or Conditioning: The cottonseed flakes are cooked or conditioned with steam to facilitate oil extraction and protein denaturation.

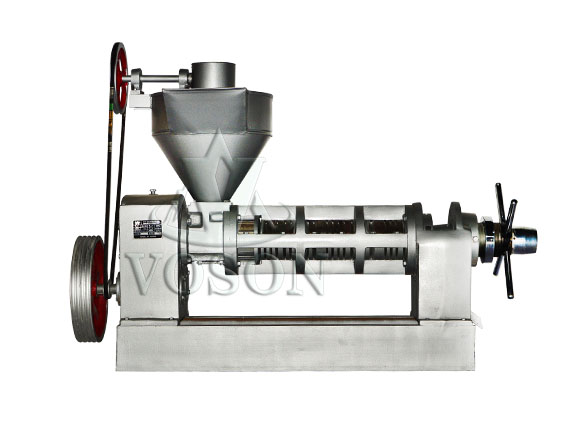

Oil Extraction: The conditioned cottonseed flakes are mechanically pressed to extract crude cottonseed oil.

Oil Filtration: The crude cottonseed oil undergoes filtration to remove solids and impurities.

Refining: The filtered crude oil is subjected to refining processes such as degumming, neutralization, bleaching, and deodorization to improve color, flavor, and shelf life.

Packaging and Storage: The refined cottonseed oil is packaged in containers suitable for storage and distribution.

These steps outline the typical process involved in extracting cottonseed oil from cottonseeds. Variations in the process may occur depending on the specific equipment used and the desired quality of the final product.

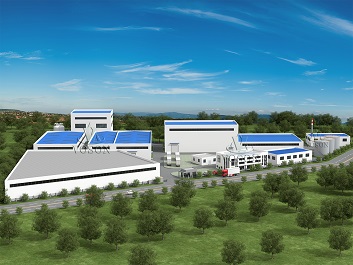

VOSON provides turn-key cottonseed oil project, cottonseed oil production line including cottonseed pre-treatment, pressing, extraction and refining to get edible cottonseed oil, also we provide update service for your old production line.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.