Features of Edible Oil Refining Equipment

Edible oil is an indispensable part of our daily diet. It not only adds deliciousness to our dishes, but also provides us with many essential nutrients. However, in order to ensure the safety, hygiene, and taste of edible oil, refining it is necessary.

Oil refining is to remove solid impurities, free fatty acids, phospholipids, colloids, waxes, pigments, odors, etc. contained in vegetable oils.

Edible oil refinery process

(1) Degumming: The process of removing colloidal impurities from crude oil using physical, chemical, or physicochemical methods is called degumming.

(2) Deacidification: Free fatty acids affect the stability and flavor of fats, and can be removed by neutralization with alkali, also known as deacidification or alkaline refining.

(3) Discoloration: Crude oil contains pigments such as chlorophyll and carotenoids. Chlorophyll is a photosensitizer that affects the stability of oil, while other pigments affect the appearance of oil and can be removed by adsorbents.

(4) Deodorization: There are some unwanted odorous substances in fats, mainly derived from the oxidation products of fats. The method of vacuum distillation is adopted, and citric acid is added to chelate excessive metal ions and inhibit oxidation.

Application of oil refining machine

The Voson Oil refining equipment can process various type of oil, like Peanut oil, soybean oil, coconut oil, sunflower seed oil, sesame oil, palm oil, rapeseed oil, castor oil, etc.

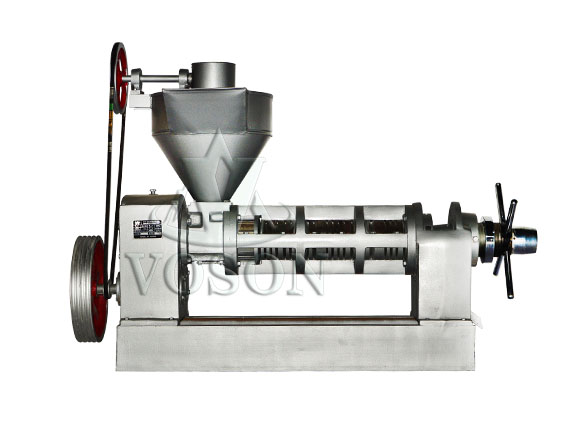

Voson edible oil refinery machine structure

The machine is consist of hydration deguming&deacidification system, filter de-coloring, transmission system, oil liquid conveying

system, transmission and lubrication system, electrical control system and machine frame

2.hydration deguming&deacidification system

This part is consist of mixer, deguming tank, gum outlet and transfer pipe

3.filter de-coloring system

This part is consist of oil inlet, a sealing cover, cover handle, fine filter bucket, oil collecting tank, filter cloth, and oil outlet.

4.transmission system

This part is consist of speed control motor, motor controller, governor and power module

5.electrical control system

This part is consist of miniature circuit breaker, motor controller, power supply module, contactor, rela

Voson Edible Oil Refining Machine Service

Pre-sale Service

(1) According to the customers' special requirements, provide the most suitable project design, process design and the purchase program.

(2) Guide customers to choose the best and economical plant, recover investment within short time, and site inspection.

On sale service

(1) Welcome you to our factory for a visiting;

(2) Accompany you to check our machine production, quality and the working conditions.

(3) Customize the equipment's strictly according to your special requirements and arrange the timely delivery.