Features of Oil Solvent Extraction

Solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and Voson is the preferred choice. Industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing. Voson-based processes have been in commercial operation for a long time.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.

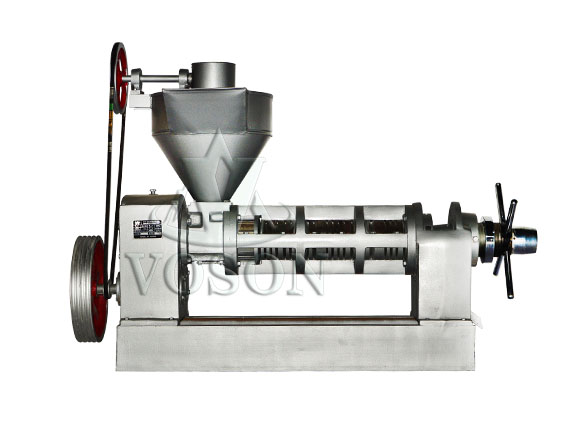

Oil Extraction Machine process

The oil raw materials are fully soaked in solvent oil and then extracted at high temperature, and processed through the "six degreasing" process (ie, degreasing, degumming, dehydration, decolorization, deodorization, and deacidification)

(1) Degumming: The process of removing colloidal impurities from crude oil using physical, chemical, or physicochemical methods is called degumming.

(2) Deacidification: Free fatty acids affect the stability and flavor of fats, and can be removed by neutralization with alkali, also known as deacidification or alkaline refining.

(3) Discoloration: Crude oil contains pigments such as chlorophyll and carotenoids. Chlorophyll is a photosensitizer that affects the stability of oil, while other pigments affect the appearance of oil and can be removed by adsorbents.

(4) Deodorization: There are some unwanted odorous substances in fats, mainly derived from the oxidation products of fats. The method of vacuum distillation is adopted, and citric acid is added to chelate excessive metal ions and inhibit oxidation.Get a Free Design

Application of Oil Solvent Extraction

The Oil Solvent Extraction can process various type of oil, like Peanut oil, soybean oil, coconut oil, sunflower seed oil, sesame oil, palm oil, rapeseed oil, castor oil, etc.Get a Free Design

Oil Solvent Extraction Advantage

High oil yield: It can efficiently extract oil from oil and increase oil production.

Low production cost: Due to the high efficiency of the leaching process and the large amount of raw material processing required, the production cost per unit of oil can be reduced.

The meal cake contains less residual oil: Compared with the pressing method, the leaching method can extract oil from the oil more effectively, resulting in a lower residual oil rate in the meal cake.

The quality of the meal is good: Since the operating conditions during the leaching process are relatively mild, the quality of the meal is good, which is beneficial to its use as feed or the extraction of plant protein from the meal.Get a Free Design

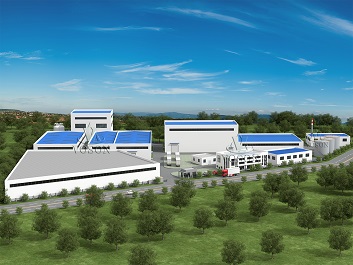

Best Oil Solvent Extraction Manufacturer

1. A Leading Oil Solvent Extraction machineManufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !