Palm oil prodution line Features

As for raw material palm seeds, VOSON provides turn-key palm oil project, palm oil prodution line including palm pre-treatment, pressing, extraction and refining to get edible palm oil, also we provide update service for your old production line.

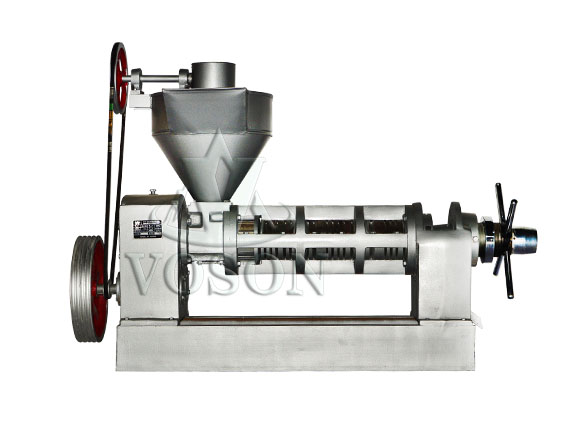

Voson Machinery has many years of excellent experience in manufacturing and installing edible oil production and processing equipment, and can undertake various types of palm oil press machine and refining machine

The production and installation of refining equipment, palm oil pretreatment equipment, and large-scale equipment for palm oil extraction can be provided. Welcome to visit and negotiate.

Palm oil making prodution process

The palm oil prodution line generally includes the following steps:

1. Picking: After the palm fruit is ripe, use a long bamboo pole to pick the palm fruit from the palm tree get down. Picking should be done in a timely manner, not too early or too late.

2.Separation: Separate the harvested palm fruits and remove the outer skin of the fruits and fruit flesh. Usually, the skin and flesh of the fruit are separated manually or mechanically.

3.Cleaning: Put the separated palm fruits into a cleaning machine for cleaning to remove the fruits surface dirt and impurities. Rinse the cleaned palm fruits with clean water.

4.Crushing: After cleaning, the palm fruit is put into a crusher for crushing, making the fruit core separate from fruit pulp. The crushed palm fruit will form a condition called palm pulp.

5.Spiral extraction: Put the palm pulp into a spiral extractor for extraction. Spiral pressing take the opportunity to separate the oil from the slurry by rotating it.

6.Separation of settling and pressing solution: After spiral pressing, the oil-water mixture obtained is called settling and pressing solution liquid, which contains palm oil and water. By using a sedimentation centrifuge or sedimentation tank, the sedimentation separate the extract to separate palm oil and water.

7.Refining: Refine the separated palm oil to remove impurities and impurities pure substance. Usually includes processes such as deacidification, phosphorus deamination, decolorization, deodorization, etc.

8.Deacidification: The acidic substances in palm oil can be removed through a deacidification device handle.

9.Phosphorus deamination: Palm oil is treated with phosphoric acid to remove its amine content.

10.Bleaching: Using substances such as activated clay or activated carbon to decolorize palm oil,

Make its color more pure.

11.Deodorization: palm oil is deodorized through vacuum distillation or short distance distillation equipment

Remove any odorous substances from it.

12.Purification: Purify the palm oil after deacidification, deamination of phosphorus, decolorization, and deodorization, remove small impurities and residual substances from it. It can be achieved through filtration, centrifugation, and other methods conduct.

13.Packaging: Refined and purified palm oil will be packaged, usually in plastic form packaging in containers such as bottles or barrels for storage and sales.

The above are the general steps of the production process of palm oil, and the specific production process will also depend on fine tune and improve according to the needs of different manufacturers and regions.Get a Free Design

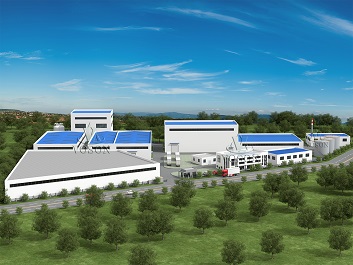

Best Palm oil Equipment Manufacturer

1. A Leading Palm oil prodution machineManufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !