Features of Peanut Oil Production Line

As for raw material peanut, VOSON provides turn-key peanut oil project, peanut oil production line including rapaseed pre-treatment, pressing, extraction and refining to get edible rapaseed oil, also we provide update service for your old production line.

Peanut is a crop with high oil content. Under certain effective conditions such as pressure, moisture, temperature and time, peanut kernels can be squeezed by hydraulic oil press to obtain peanut oil with apricot yellow color, original flavor, fragrant smell and pure taste.

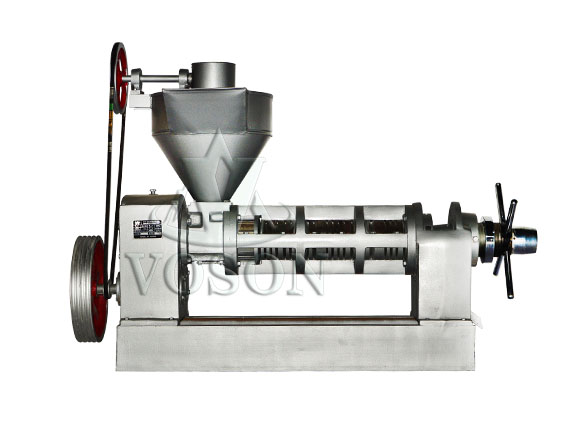

The peanuts are crushed, selected (to separate the peanuts from the shells), stir-fried until 6-8 hours of maturity, and then physically squeezed by an oil press. The products after squeezing are squeezed peanut oil and peanut residue, which is edible. The oil press is divided into vertical oil top oil press and screw oil press.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.

Peanut oil making prodution process

1、Raw material processing: First, high-quality peanuts are purchased as raw materials. These peanuts need to go through screening, cleaning and impurity removal processes to ensure their good quality.

2、Crushing and selection: Peanuts are crushed to become peanut blanks. This step helps to change the size of the oilseed particles, which is conducive to the subsequent rolling and pressing process.

3、Steaming and frying: The crushed peanut blanks are first steamed, and then enter the frying stage. They can be taken out of the pot when they are golden, shiny and fragrant. The purpose of steaming and frying is to completely destroy the oilseed cells, denature the protein, and aggregate the oil, which is convenient for subsequent pressing.

4、Pressing: Use traditional vertical oil-top oil presses or modern hydraulic presses to squeeze the oil out of the peanut blanks.

5、Sedimentation and filtration: The newly squeezed peanut oil needs to be precipitated. After a period of standing, the impurities and water in it are allowed to settle. Subsequently, the remaining impurities and suspended matter are removed by filtering equipment to obtain relatively pure peanut oil.

6、Deodorization and refining (optional): In order to further improve the quality of peanut oil, deodorization and refining processes may be carried out. Deodorization usually uses steam distillation to remove volatile substances from crude oil; refining includes steps such as decolorization and deacidification to improve the taste and stability of peanut oil.

7、Filling and packaging: Finally, the peanut oil that has undergone the above treatment will be filled and packaged for easy storage and sale. Get a Free Design

Best Peanut Oil Press Equipment Manufacturer

1. A Leading Peanut oil prodution line machine Manufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !