Rapeseed/Canola oil prodution line Features

As for raw material rapaseed/canola, VOSON provides turn-key rapaseed oil project, rapaseed/canola oil prodution line including rapaseed pre-treatment, pressing, extraction and refining to get edible rapaseed oil, also we provide update service for your old production line.

Voson Machinery has many years of excellent experience in manufacturing and installing edible oil production and processing equipment, and can undertake various types of rapaseed oil press, rapaseed oil refining

The production and installation of refining equipment, rapaseed oil pretreatment equipment, and large-scale equipment for rapaseed oil extraction are welcome to our customers visit and negotiate.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.

Canola oil making prodution process

The process of rapeseed/canola oil production involves several steps, from preliminary treatment to final refining and packaging to ensure the quality and safety of the product. Here are the main steps in canola oil processing:

Preliminary treatment:

Screening: First, the rapeseed is screened to remove plant debris and debris through a vibrating screen. Clean rapeseed passes through the filter and impurities are separated.

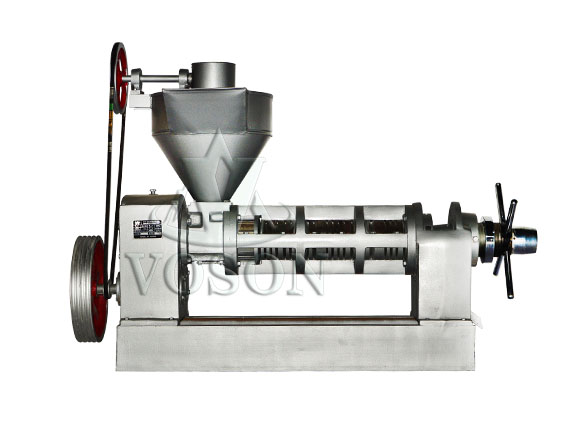

Pressing: The screened rapeseed is fed into a press, which is pressed into flakes by the squeezing action of steel rollers. These flakes are then fed into a screw press, where high-pressure pressing is used to squeeze the oil out of the flakes.

Chemical extraction: The screw press can extract three-quarters of the oil in the rapeseed, leaving the rest of the oil in the residue called rapeseed cake. The rapeseed cake is soaked in a chemical solvent and the remaining oil is extracted through a chemical extraction process.

Refining:

Washing: The extracted oil goes through a washing process, using sodium hydroxide for 20 minutes, and the centrifugal force of high-speed rotation helps separate natural impurities.

Dewaxing: The washed rapeseed oil is cooled to 5 degrees Celsius to thicken the natural wax and make it easier to filter and remove.

Bleaching and decolorization: The rapeseed oil undergoes a bleaching and color reduction process, as well as a steam jet heating process to remove odor and color.

Packaging and quality inspection:

Bottling: The refined rapeseed oil is bottled in plastic bottles, and the bottling machine we also supply Get a Free Design

Best Rapeseed Oil Press Equipment Manufacturer

1. A Leading rapeseed oil making machine manufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !