The rapeseed oil extraction process (rapeseed oil project) generally includes the following main steps:

Cleaning and Sorting: Rapeseeds harvested are cleaned to remove surface dirt, impurities, and other foreign matter. Subsequently, the seeds are sorted to eliminate small particles and non-conforming seeds.

Drying: The cleaned rapeseeds are dried to reduce moisture content, typically to a controlled level to enhance oil extraction efficiency and quality.

Crushing and Grinding: The dried rapeseeds are passed through crushers and grinders to break them into particles suitable for subsequent pressing. This increases the surface area of the seeds, improving oil extraction efficiency.

Heat Treatment: Heat treatment, such as steaming or microwave heating, is applied to the crushed rapeseeds to soften the seed cells, facilitating oil release and extraction.

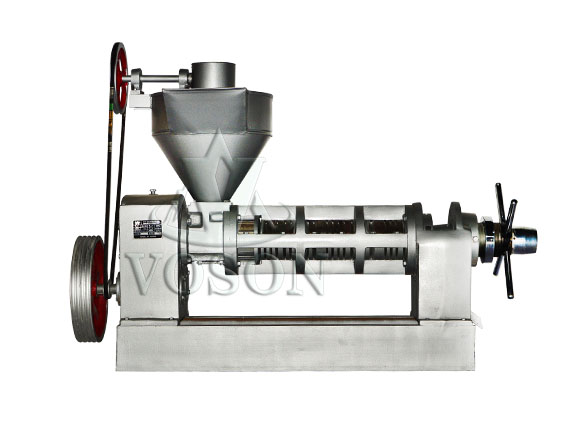

Pressing: Mechanically or hydraulically press the prepared rapeseeds to extract oil by applying pressure to squeeze the oil from the seeds.

Oil Filtration and Separation: Filter the crude oil obtained through preliminary filtration to remove suspended particles and impurities. Follow with centrifugal separation to separate the oil from the oil-water mixture.

Deodorization and Decolorization: Subject the separated oil to deodorization to remove unwanted odors through distillation or physical adsorption. Then, decolorize the oil using adsorbents like activated clay or activated carbon to remove pigments and other impurities, resulting in a clear or light yellow oil.

Refining and Storage: The deodorized and decolorized oil undergoes further refining processes including dehydration, deacidification, and removal of solvent residues to improve its quality and stability. Finally, store the refined oil in appropriate containers for packaging and sale.

The specific steps and equipment selection in the rapeseed oil extraction process may vary depending on production scale, technological advancements, and market demands, but the above steps typically constitute a complete rapeseed oil extraction production process.

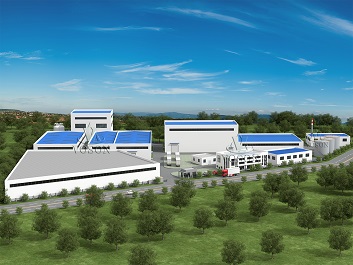

VOSON provides turn-key rapeseed oil project, rapeseed oil production line including rapeseed pre-treatment, pressing, extraction and refining to get edible rapeseed oil, also we provide update service for your old production line.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.