Features of Rotary extractor

Rotary extractor is a device commonly used in the chemical industry for separating and extracting components from mixtures. It typically consists of a vertical cylindrical vessel filled with fixed packing material such as packing balls or packs. These packing materials provide a large surface area, facilitating effective contact between the solvent flowing through the interior and the mixture.

In the process of edible oil extraction, a packed bed extractor is commonly used. This equipment is employed to extract oils from plant materials such as soybeans, sunflower seeds, peanuts, and others. These oils are further processed for food or industrial purposes. The packed bed extractor facilitates efficient extraction by allowing thorough contact between the solvent and the plant material.

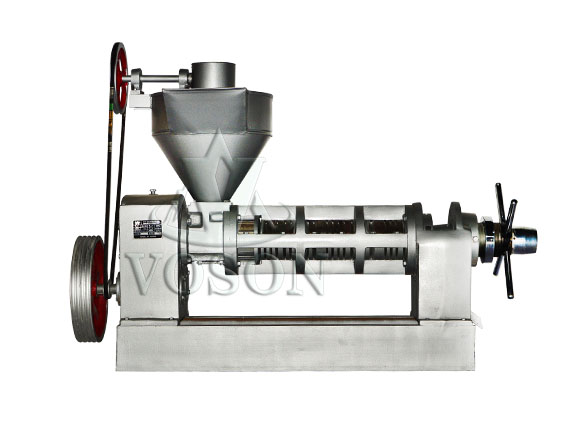

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.

Rotary extractor Applications

Selection of Packing Material: The extractor is filled with high-surface-area packing material, typically spherical or cylindrical in shape, such as packing balls or packs. These materials provide ample contact surface for the solvent to interact with the oils in the plant material.

Solvent Flow: Solvent (such as hexane or ethyl acetate) is introduced into one end of the packed bed extractor and flows through the packing material. The choice of solvent depends on its ability to dissolve the target components (oils) and its ease of subsequent recovery.

Oil Extraction: Prepared plant material (often crushed or pre-treated) passes through the packed bed extractor, where it comes into contact with the flowing solvent. Oils dissolve into the solvent, forming a solution.

Solvent Recovery: The solution exiting the packed bed extractor contains extracted oils and solvent. The solvent can be separated and recovered for reuse through distillation or other recovery methods.

Oil Collection: The extracted oils are separated from the solvent that flows out of the extractor. This typically involves solvent removal or distillation to recover oils.

VOSON provides turn-key oil project, oil production line including oil seed pre-treatment, pressing, extraction and refining to get edible oil, also we provide update service for your old production line.

The Extractor equipment can use various type of oil, like Peanut oil, soybean oil, coconut oil, sunflower seed oil, sesame oil, palm oil, rapeseed oil, castor oil, etc.

Voson Rotary extractor Advantages

1. Improved extraction efficiency compared to traditional static methods.

2.Increased oil yield due to continuous circulation of solvents and oil materials.

3.Reduced solvent usage, leading to cost savings and environmental benefits.

4.Lower energy consumption as a result of optimized circulation processes.

5.Enhanced control over extraction parameters such as temperature and pressure.

6.Consistent product quality achieved through precise parameter management.

7.Suitable for large-scale production environments, ensuring high throughput.

8.Minimized processing time for oil extraction operations.

9.Versatile application across various oilseed and chemical extraction processes.

10.Compatibility with modern automation and monitoring systems.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !