Soybean Oil Prodution Line Features

As for raw material soybean seeds, VOSON provides turn-key soybean seed oil project, soybean oil prodution line including soybean pre-treatment, pressing, extraction and refining to get edible soybean oil, also we provide update service for your old production line.

Soybean oil is generally processed by various methods such as pressing and leaching to obtain crude oil with more impurities, which is then refined to obtain edible refined oil.

Henan Voson Grain Machinery is a manufacturer specializing in the manufacture of edible oil production line (10~500ton/day). Like Coconut oil prodution line、Soybean Oil Prodution Line、Peanut oil prodution line、Sunflower oil prodution line, produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Oil Press Plant (10~500ton/day), you are welcome toContact Us.

Soybean Oil Making Prodution process

The production process of soybean oil mainly includes cleaning, crushing, softening, flaking, steaming, pressing or leaching, filtering, refining and other steps. The following is a detailed process description:

Cleaning: Remove impurities such as sand, stones, dust, metal particles, etc. in soybeans to avoid equipment wear and improve the oil yield and quality of soybeans.

Crushing: Use crusher equipment to crush large-grain soybeans so that their particle size meets the conditions for flaking, and increase the surface area of soybeans, which is conducive to the transfer of temperature and water.

Softening: It is carried out in a softening pot to increase the extensibility of soybeans and make them more suitable for flaking.

Flaking: The softened soybeans are rolled into thin sheets by the flaking machine so that it is easier to extract oil during the pressing or leaching process.

Steaming: The soybeans after flaking are steamed and fried to adjust the temperature and humidity of the soybeans, which is conducive to the subsequent pressing or leaching process.Get a Free Design

Pressing or leaching:

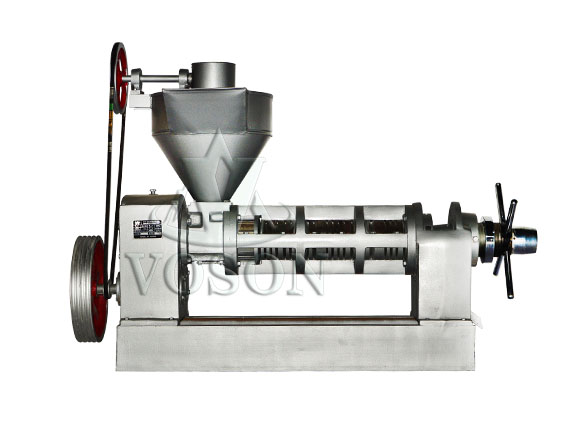

Pressing method: There are two types: ordinary pressing and spiral pressing. The screw pressing method installs a screw shaft in the cylinder of the horizontal device. After the pretreated soybeans enter the screw press, the oil is squeezed out while moving forward. This method can be produced continuously, but during the oil pressing process, due to friction and heat, the protein often changes to a large extent.

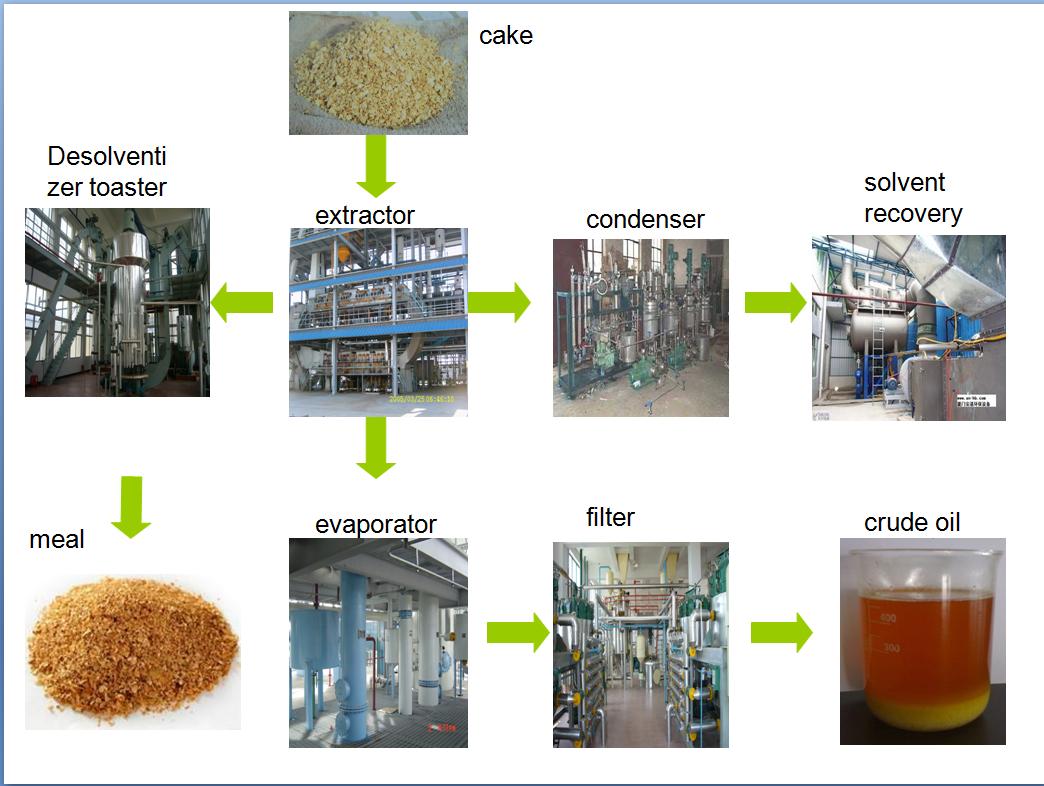

Extraction method: Use a solvent that can dissolve oil (such as light gasoline) to extract the oil in the billet through wetting penetration, molecular diffusion and convection diffusion. Then, the mixed oil composed of solvent and fat is separated, and the solvent is recovered to obtain crude oil. The oil yield of the extraction method is as high as 99%, but the refining process may cause the loss of some vitamins.

Filtration: Filter the crude oil obtained by pressing or leaching to remove impurities.

Refining: Including degumming, deacidification, decolorization, deodorization and other processes to remove colloid, color acid, odor, etc. in the crude oil to meet the edible oil standards and hygiene requirements. The refined soybean oil can be filled and become soybean oil sold on the market.Get a Free Design

Best Soybean Oil Press Equipment Manufacture

1. A Leading soybean oil press machine manufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !